Using Transistor as a Switch

源自於 http://www.ermicro.com/blog/?p=423

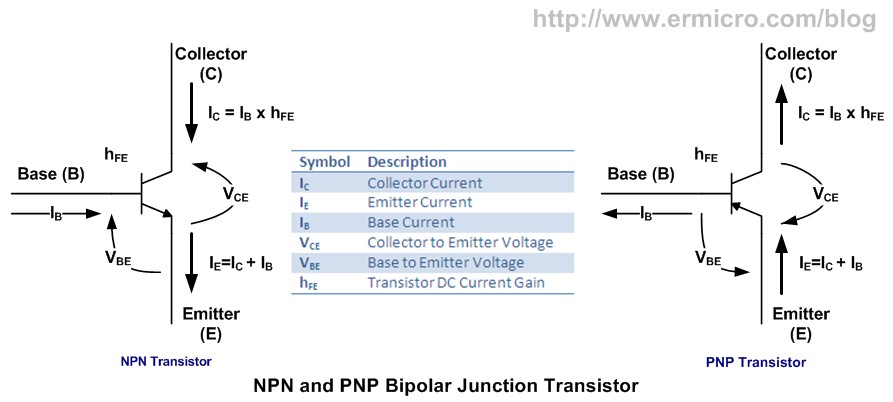

Most of microcontrollers work within 5 volt environment and the I/O port can only handle current up to 20mA; therefore if we want to attach the microcontroller’s I/O port to different voltage level circuit or to drive devices with more than 20mA; we need to use the interface circuit. One of the popular method is to use the Bipolar Junction Transistor (BJT) or we just called it transistor in this tutorial. I have to make clear on this BJT type to differentiate among the other types of transistors family such as FET (Field Effect Transistor), MOSFET (Metal Oxide Semiconductor FET), VMOS (Vertical MOSFET) and UJT (Uni-Junction Transistor).

A. The Switch

The transistor actually works as a current gainer; any current applied to the base terminal will be multiplied by the current gain factor of the transistor which known as hFE. Therefore transistor can be used as amplifier; any small signal (very small current) applied to the base terminal will be amplified by the factor of hFE and reflected as a collector current on the collector terminal side.

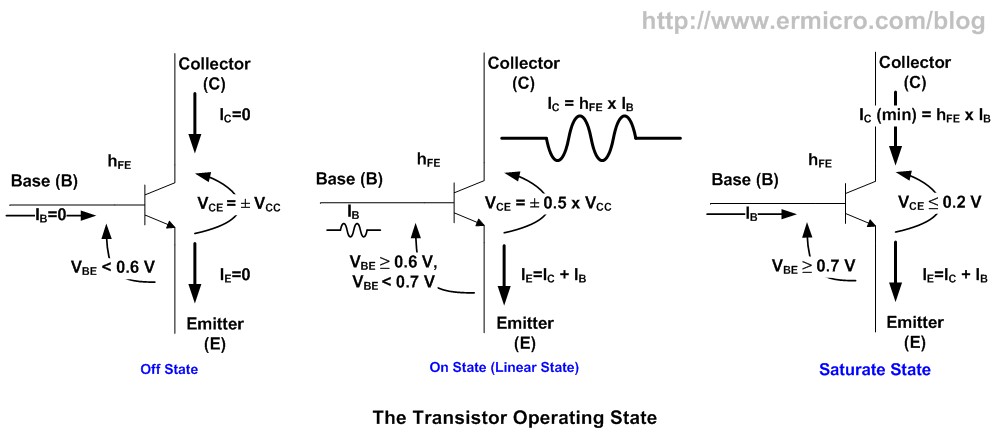

All the transistors have three state of operation:

- Off state: in this state there is no base current applied or IB = 0.

- On active state: in this state any changes in IB will cause changes in IC as well or IC = IB x hFE. This type of state is suitable when we use transistor as a signal amplifier because transistor is said is in the linear state. For example if we have a transistor with gain of 100 and we increase the IB from 10uA to 100uA; this will cause the IC to swing from 1000uA to 10000uA (1 mA to 10 mA).

- On saturate state: in this state any changes in IB will not cause changes in IC anymore (not linear) or we could say IC is nearly constant. We never use this state to run the transistor as a signal amplifier (class A amplifier) because the output signal will be clamped when the transistor is saturate. This is the type of state that we are looking for on this tutorial.

From the picture above we could see the voltage and current condition of transistor on each state; if you notice when transistor is in off state the voltage across collector and emitter terminal is equal to the supplied voltage, this is equivalent to the open circuit and when transistor is in saturate state the collector to emitter voltage is equal or less then 0.2 Volt which is equivalent to the close circuit. Therefore to use transistor as a switch we have to make transistor OFF which equivalent to the logical “0” and SATURATE which is equivalent to the logical “1“.

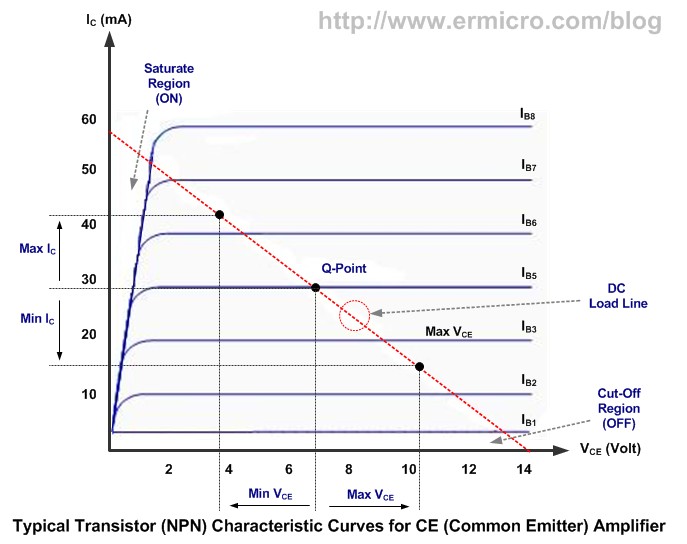

One of the famous diagrams that show the transistor operating state is called the transistor static characteristic curve as shown on this following picture:

When we operate transistor as the class A common emitter amplifier usually we choose to bias the transistor (apply voltage on VBE and VCE) in such a way (Q-Point) that IC and VCE (output) will swing to its maximum or minimum value without any distortion (swing into the saturation or cut-off region) when the IB (input) swing to its maximum or minimum value; but when we operate the transistor as switch we intentionally push the transistor into its saturation region to get the lowest possible VCE(i.e. near 0.2 volt) when we need to make the transistor ON (switch ON) and into its cut-off region when we need to make the transistor OFF (switch OFF).

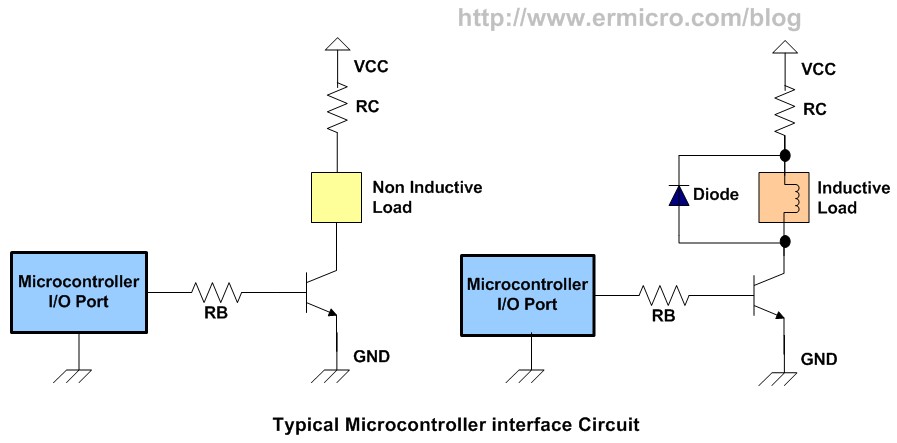

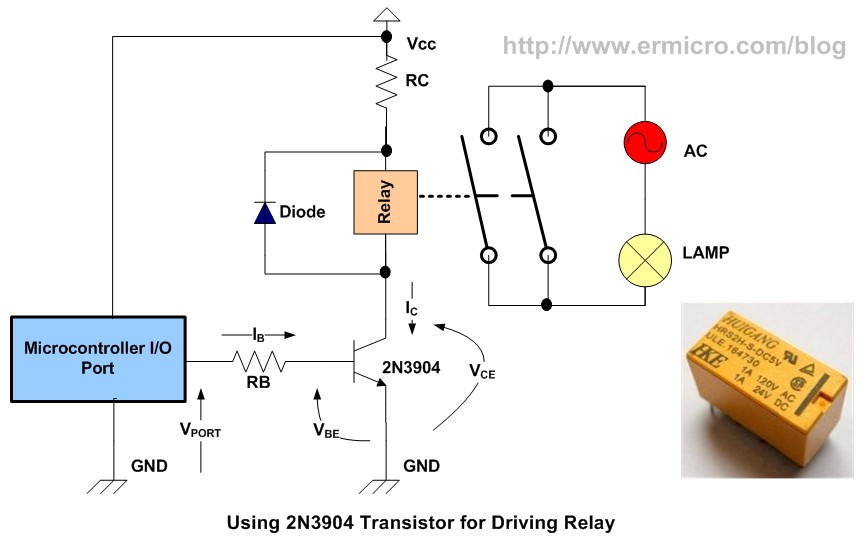

The above diagram show a typical microcontroller interface circuit using NPN transistor; the RBresistor is used to control the current on base terminal that make transistor OFF and ON (saturate); while the RC resistor is the current limiter for the load. if the load operate with the same voltage as the supplied power (Vcc) you can by pass the RC (not use).

Notice the diode (also known as the clamp diode) in the inductive load circuit is needed to protect the transistor again the EMF (Electromotive Force) voltage generated by the inductor component when the transistor is switched on and off rapidly, this voltage is oppose the source voltage. The diode will act as a short circuit to the high voltage generated by the inductor component, you can use any general purpose diode with capable on handling minimum 1 A of current such as 1N4001, 1N4002, etc.

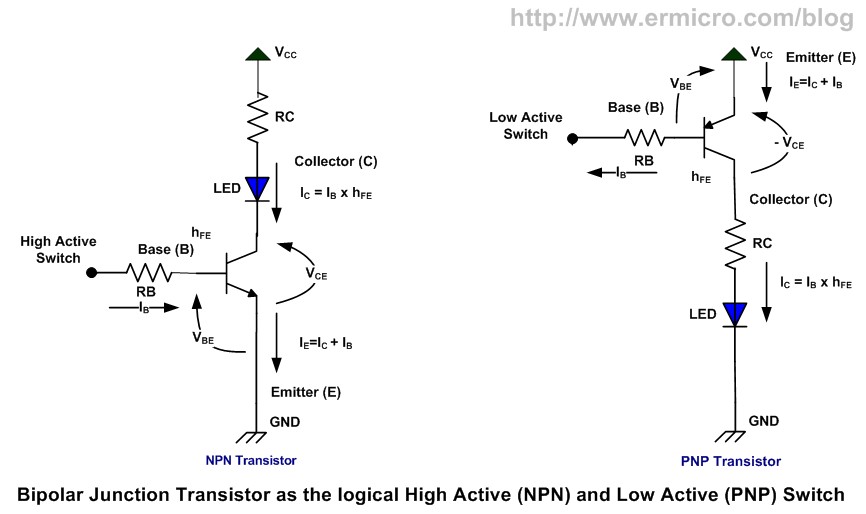

On the picture shown above you could see how we connect the transistor as the high active switch (logical high) also known as low side switch using NPN transistor and the low active switch (logical low) also known as high side switch using PNP transistor.

Ok let’s calculate each of the RB and RC value on this following NPN transistor circuit:

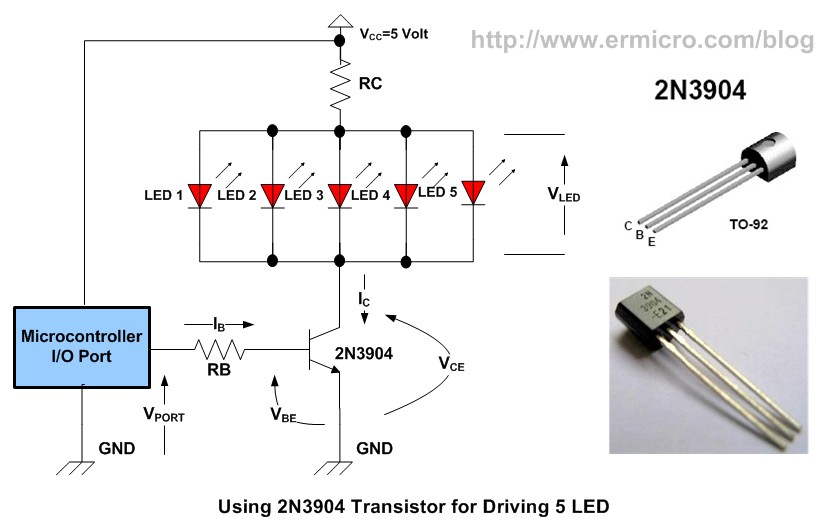

On the circuit above we are going to use 2N3904 (the cheap general purpose transistor where you could easily found on your local market) to drive 5 LED from microcontroller port, from the 2N3904 datasheet we get this following information:

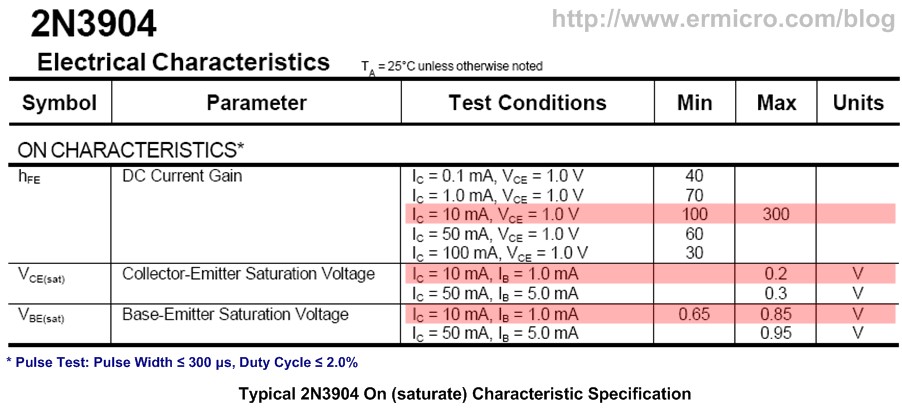

IC max = 200mA (this is maximum value that will make your transistor smoked, in practical application always use just half of the maximum value mentioned on the datasheet), hFE = 100 to 300, VBE saturate = 0.65 Volt, VCE saturate = 0.2 Volt

For most transistor in general we can use VBE = 0.7 Volt (should be saturate) and VCE = 0 Volt. Using the 5 volt power supply (VCC) and assuming VLED = 2 Volt, with each of them consuming 15 mA, we could calculate the RC value using the Ohm’s law as follow:

IC = 5 x 15 mA = 75mA (0.075 A), this current is still far bellow the maximum IC allowed by 2N3904 transistor.

RC = (VCC – VLED) / IC = (5 – 2) / 0.075 = 40 Ohm

Power Dissipation on the RC resistor will be

P = (VCC – VLED) x IC = (5 – 2) x 0.075 = 0.225 Watt

Base on the above calculation we could use the nearest higher value available on the market; which is 47 Ohm, 0.5 watt resistor (for heat dissipation usually we use twice of the watt value calculated).

Assuming the hFE minimum is 100; the minimum current required in the transistor’s base terminal to drive the LED is:

IC = hFE x IB

IB = IC / hFE = 0.075 / 100 = 0.00075 A (0.75 mA)

IB = IC / hFE = 0.075 / 100 = 0.00075 A (0.75 mA)

This current can easily be supplied by most microcontroller I/O port; which is capable to drive up to 20 mA output current. Again by applying the Ohm’s law we could calculate the RB value as follow:

RB = (VPORT – VBE) / IB

Assuming the minimum average voltage of microcontroller I/O port (VPORT) with logical “1” is about 4.2 volt (the microcontroller is powered by 5 volt supply):

RB = (4.2 – 0.7) / 0.00075 = 4666.66 Ohm

Power dissipation on the RC resistor will be

P = (VPORT – VBE) x IB = (4.2 – 0.7) x 0.00075 = 0.002625 Watt

Base on the result you could use 4K7 Ohm, 0.25 Watt resistor (this is the common resistor which you could easily found on the local market i.e. 0.25 watt and 0.5 watt).

Use this RB calculation as your maximum reference value; in the real world most of the transistorshFE is vary and being measured (tested) with different VCE and IC value not to mention different specification even though you use the same transistor type. Therefore the real RB value could be lower than 4K7 if you really want to drive the transistor into its fully saturate mode where the VCEnear 0.2 volt.

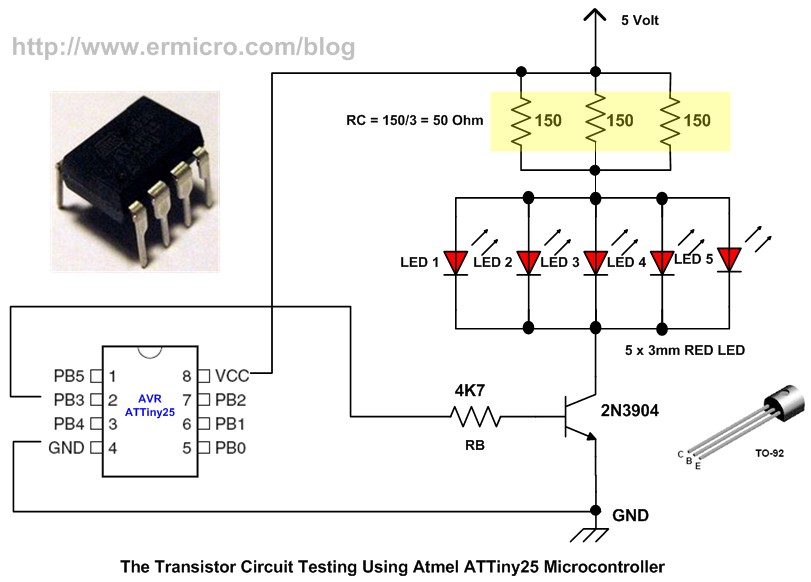

Now the question is how we determine the exact value? To answer to this question I build this following testing circuit base on the RC and RB calculated value above using the Atmel AVR ATTiny25 microcontroller to blink the five LED:

Note: the reason I used RC = 3×150 Ohm because at that time I run out the required 47 Ohm resistor, therefore you could use just single 47 Ohm resistor or if you only have 150 Ohm as I did, you could use them as I did.

Bellow is the C Program that I used to test this circuit:

//*************************************************************************** // File Name : trswitch.c // Version : 1.0 // Description : Transistor as Switch: Simple LED Blinker // Author : RWB // Target : Atmel AVR ATTiny25 Microcontroller // Compiler : AVR-GCC 4.3.0; avr-libc 1.6.2 (WinAVR 20090313) // IDE : Atmel AVR Studio 4.17 // Programmer : Atmel AVRISPmkII // Last Updated : 1 November 2009 //*************************************************************************** #include <avr/io.h> #include <util/delay.h>

int main(void)

{

// Initial I/O

DDRB |= (1<<PB3); // Set PB3 as Output, Others as Input

PORTB &= ~(1<<PB3); // Reset the PB3

for(;;) { // Loop Forever

PORTB |= (1<<PB3); // Port PB3 High

_delay_ms(3000); // Delay 3 Second

PORTB &= ~(1<<PB3); // Port PB3 Low

_delay_ms(1000); // Delay 1 Second

}

return 0; // Standard Return Code

}

/* EOF: trswitch.c */

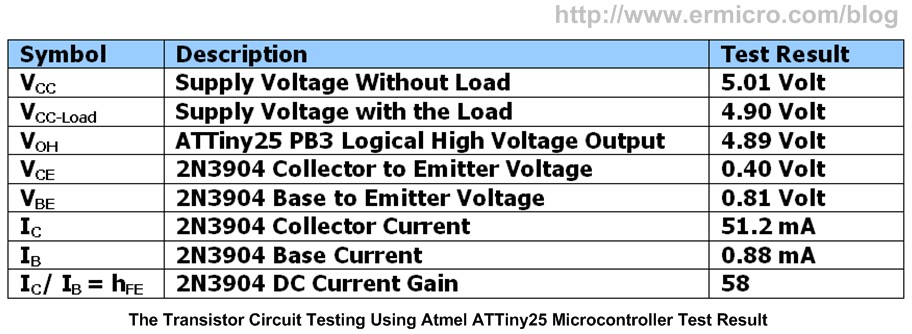

The program simply blink all the LED by toggling the AVR ATTiny25 microcontroller PB3 output port high for about 3 second and low for about 1 second and here is the test result when the PB3 port swing to the logical high:

As you’ve seen from the result there is about 0.4 volt drop on the collector to emitter (VCE) terminal instead of 0 Volt as we assume on the above calculation and the DC current gain is about 58 instead of 100 again as we assume on the above calculation. Now you understand there are tremendous different result between the 2N3904 transistor datasheet and my test circuit, this is because the 2N3904 datasheet is measured using the PWM (Pulse Width Modulation) with period for about 300 us (micro second) and duty cycle for about 2%, the reason to use this very short pulse period method in the measurement is because they don’t want to overheat the transistor junction; where this junction heating will vary the transistor hFE measurement significantly.

On my test circuit above; I used 3 second to make the 2N3904 transistor ON (saturate, VBE = 0.81 Volt, VCE = 0.4 Volt) and 1second to make it OFF. The other factor that make the test result differ is the various manufacture specification even though we used the same transistor type. Therefore the answer to the above question is; there is no exact value for RC and RB; is depend on your application but it save to use the above method to calculate the RC and RB and then do the circuit prototyping to test your design, next adjust your RC and RB value accordingly.

Some calculation suggestion is to use the collector to base current ratio of 10 (regardless of the transistor hFE value) to force the transistor into fully saturate (VCE = 0.2 Volt, as shown on the datasheet above) by using this following formula:

IB = IC / hFE = IC / 10

This is what I called a “maximum saturate calculation method” (also known as worst-case design procedure), again as you’ve seen from the real test circuit result above even though we drive the VBEmore than 0.7 volt, we still get the hFE for about 58 and IB for about 0.88 mA which is useful in the microcontroller application (for more information you could read “Powering Your Microcontroller’s Base Project” on this blog), therefore for practical application I would suggest; if you want to use this maximum saturate calculation method to determine the base resistor (RB) value, make sure at least you double the calculated value. For example to determine the RB on the test circuit above using this maximum saturate calculation method:

IB = IC / hFE = 0.075 / 10 = 0.0075 A (7.5 mA)RB = (4.2 – 0.7) / 0.0075 = 466.66 Ohm

By using twice the calculated value you will get 933.32 Ohm, or you could use the 1K Ohmstandard resistor.

In typical rapid switching transistor application actually we don’t drive the transistor into its full saturate state (i.e. VCE = 0.2 Volt), because when the transistor is fully saturate, it tend to have a longer switching time (i.e. from ON to OFF to ON again). The VCE = 0.4 volt as shown on the real test circuit above is already adequate for most switching application, while we could still take advantage of the low transistor base current (i.e. IB = 0.88 mA). You could see this test circuit on the video at the end of this article.

B. Driving the Relay

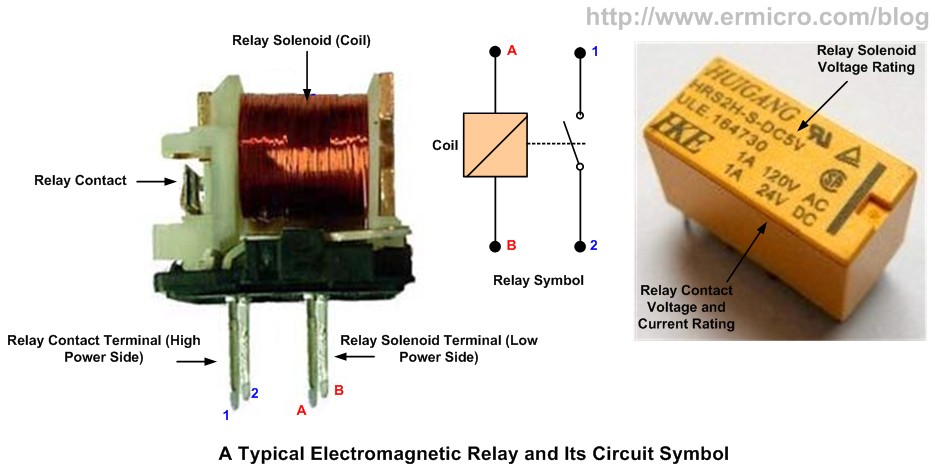

Relay perhaps is one of the oldest electronic components that could be tracked back from the early years when we first use the electricity in our life. A relay basically is an electrical switch that uses the electromagnetic solenoid to control a switch contact. Because it use the solenoid (inductive load), therefore we need to use a diode to protect the transistor against the EMF. The main advantage of using a relay is that we could “relaying” or pass on the switch effect from a low power side on its solenoid to the high power side on its metal contact by using the electromagnetic effect, where both of the solenoid and contact has its own separate electrical specification.

Now using the same principal we could easily calculate the RC and RB value on this following circuit:

By using 5 Volt power supply and relay with 5 Volt and 60mA operating current:

RC = 0 Ohm (not use, connect relay directly to VCC)

IB = IC / hFE = 0.06 A / 100 = 0.0006 A

RB = (VPORT – VBE) / IB = (4.2 – 0.7) / 0.0006 = 5833.33 Ohm, use 5K6 Ohm resistor

P = (VPORT – VBE) x IB = (4.2 – 0.7) x 0.0006 = 0.0021 watt, use 0.25 Watt resistor

IB = IC / hFE = 0.06 A / 100 = 0.0006 A

RB = (VPORT – VBE) / IB = (4.2 – 0.7) / 0.0006 = 5833.33 Ohm, use 5K6 Ohm resistor

P = (VPORT – VBE) x IB = (4.2 – 0.7) x 0.0006 = 0.0021 watt, use 0.25 Watt resistor

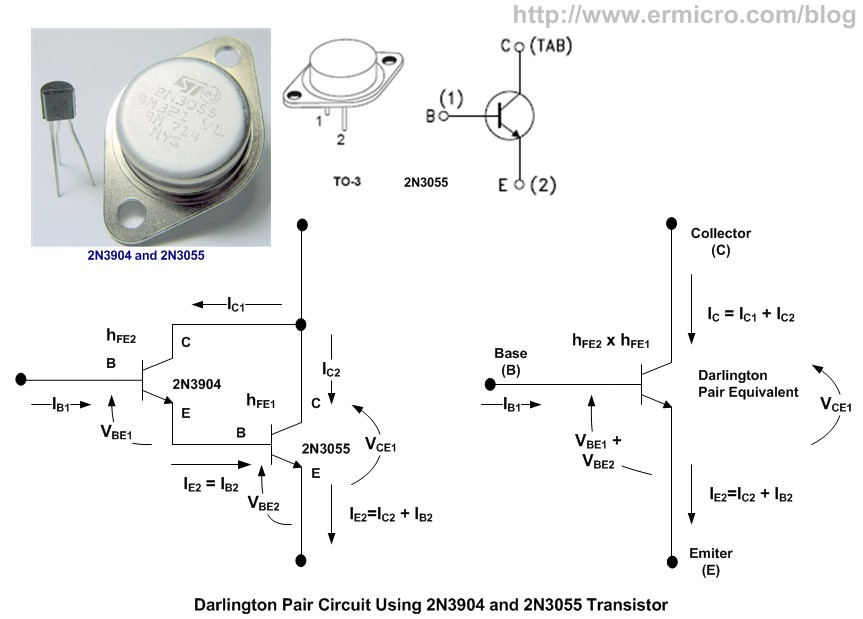

C. Increasing the Collector Current

What if the load current is more than 1 A, let’s say you want to drive a DC motor? Perhaps you will think to use bigger transistor such as 2N3055 power transistor; unfortunately the big power transistor tends to have small hFE mostly less then 20, so it’s mean we have to supply bigger base current. We know that most microcontrollers I/O port can only supply a current up to 20mA, therefore by using this type of transistor the maximum current that we could achieve in the collector terminal is about 400mA; which is far bellow our expectation. The solution for this situation is to use what known as Darlington pair circuit:

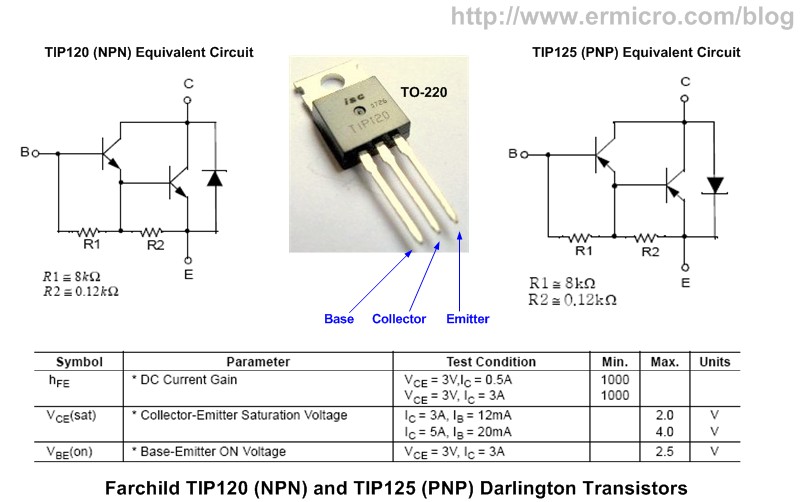

By using the Darlington pair circuit we could combine two transistors; one with high hFE2 factor usually has a low collector current and the one with high collector current usually has a lowhFE1factor. This will give you a total hFE of hFE1 x hFE2. In the Darlington pair circuits the VBE will be twice the normal transistor saturated voltage which is about 1.4 Volt. One of the popular ready made Darlington pair transistors on the market are TIP120 (NPN type) and TIP125 (PNP type) which could handle the collector current up to 3 A (max 5 A), and has the hFE minimum of 1000.

The TIP120 and TIP125 is called a pair Darlington transistors as they have similar characteristic but have an opposite type (i.e. NPN and PNP), this Darlington transistor pair is popular used in motor controller with the H-Bridge circuit. Remember when you use a power transistor to drive a large collector current, you need to supply the transistor with the adequate heat sink to help cooling the transistor by dissipating heat through the heat sink surface into the surrounding air.

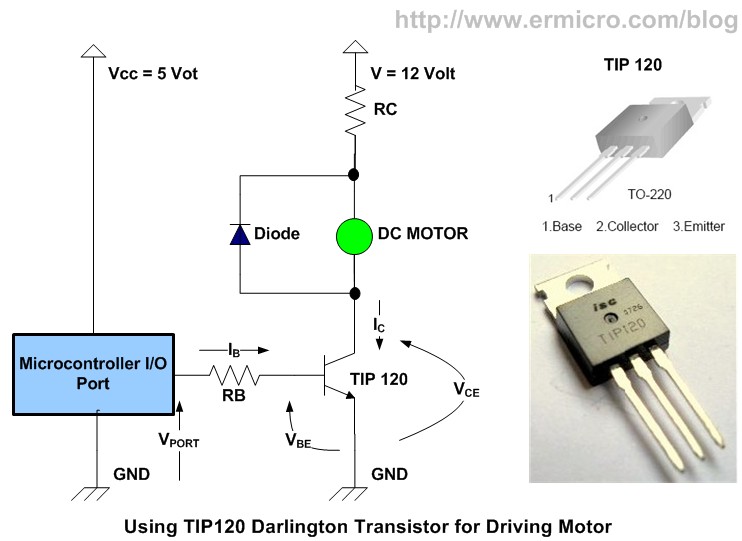

Using the same principal we’ve learned before, we could easily calculate the RB value of the DC motor circuit interface bellow:

By using 5 Volt power supply and DC Motor with 12 Volt and 1 A maximum operating current:

RC = 0 Ohm (not use, connect directly to the 12 Volt power)

IB = IC / hFE = 1 A / 1000 = 0.001 A

RB = (VPORT – VBE) / IB = (4.2 – 1.4) / 0.001 = 2800 Ohm, use 2K7 Ohm resistor

P = (VPORT – VBE) x IB = (4.2 – 1.4) x 0.001 = 0.0028 watt, use 0.25 Watt resistor

IB = IC / hFE = 1 A / 1000 = 0.001 A

RB = (VPORT – VBE) / IB = (4.2 – 1.4) / 0.001 = 2800 Ohm, use 2K7 Ohm resistor

P = (VPORT – VBE) x IB = (4.2 – 1.4) x 0.001 = 0.0028 watt, use 0.25 Watt resistor

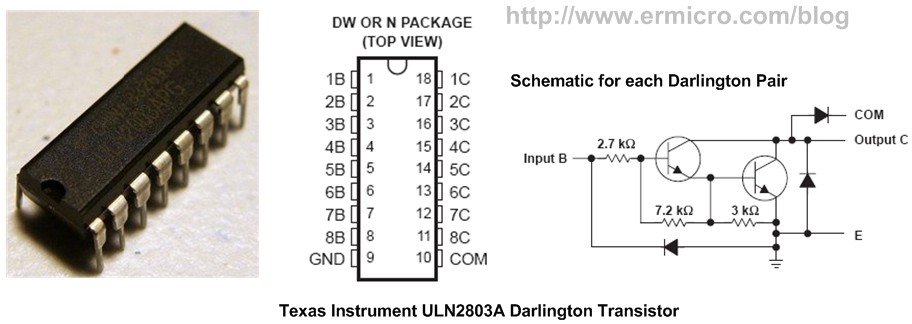

D. The Darlington Transistor Array

For more compact version of the Darlington pair transistor you could use the Texas Instrument ULN2803A which is contain 8 Darlington pair transistors with has build in 2K7 base resistor and clamp diode for each Darlington pair transistors. This makes this Darlington transistor array suitable for driving the relay or motor up to 500mA (this is a maximum datasheet value) directly from the microcontroller output.

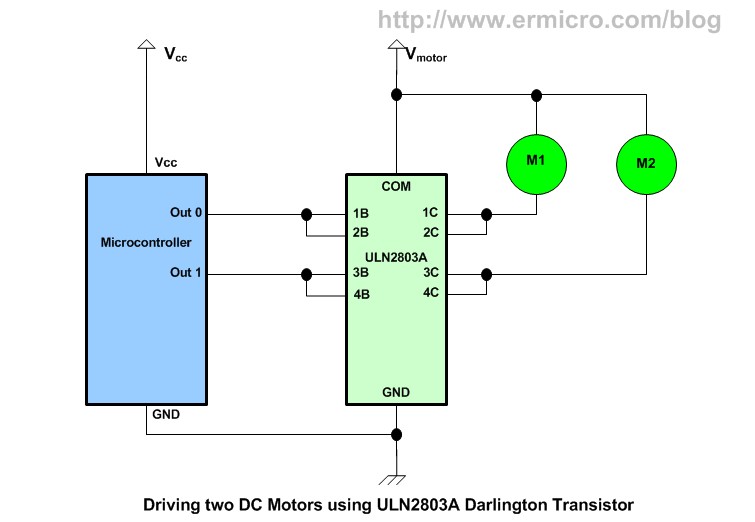

To increase the output current up to 1 A (2 x 500mA, remember this is a maximum datasheet value, for practical application use just half or 2 x 250 mA) you could simply use two Darlington transistor array connected in parallel, the following is the sample circuit for driving two DC motors using the ULN2803A Darlington transistor array:

Thanks to the build in internal 2K7 base resistor and the two clamp diode, you don’t need any external component when using ULN2803A to drive the DC motor from your microcontroller port. The Darlington transistor array ULN2803A could be used to drive up to 50 volt voltage load.

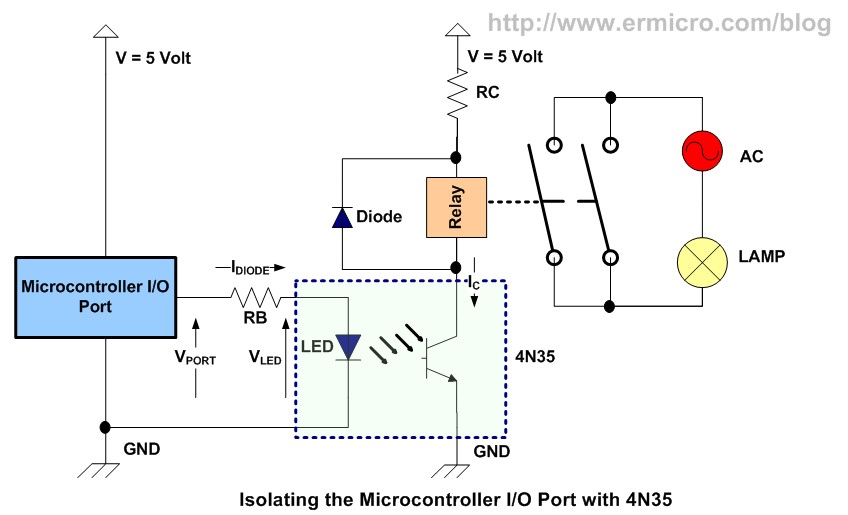

E. Isolating your Circuit

Sometimes we need to isolate our microcontroller circuit from the interface circuit especially in the environment that generating a lot of noise which could disturb our microcontroller operation. When we use a relay from the above example, the driver ground is still directly connected to the microcontroller circuit, so there is a change the noises will interfere the microcontroller circuit.

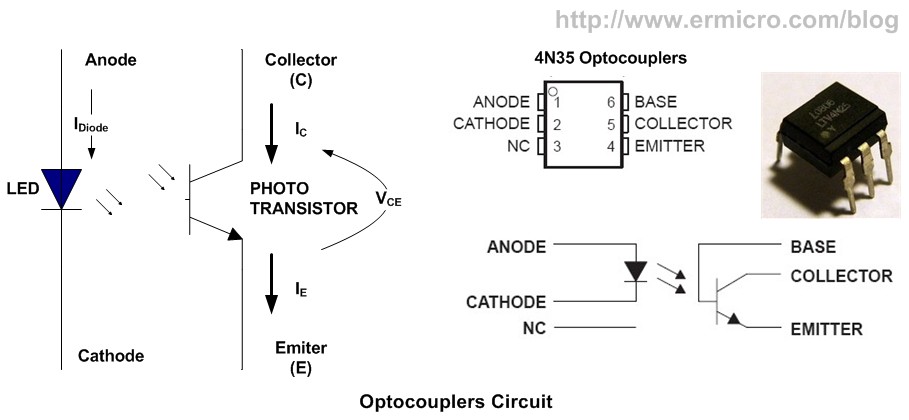

To completely isolate the circuit we could use the optocouplers (also called optoissolator) circuit, this circuit will completely isolate your microcontroller from the interface circuit:

The popular optocouplers circuit available on the market is 4N35 which has the hFE of 500 (in the optocouplers terminology this is also known as the transistor static forward current transfer ratio, Texas Instrument SOES021C, measured with infrared LED current = 0) and maximum collector current of 100mA.

Differ from the ordinary transistor in the optocouplers we don’t use the transistor base terminal for driving the collector current; instead we use the internal infrared LED to transfer the infrared LED light intensity to the phototransitor; based on this infrared LED light intensity the phototransistor will be turned ON or OFF; giving more current to drive this infrared LED will effect more current to flow on the phototransistor collector; This effect is known as the current transfer ratio (CTR). The 100% CTR means that all the current flow on the infrared LED will be transferred 100% to the phototransistor collector.

Therefore by driving the internal infrared LED with 15 mA (in the optocouplers terminology this is also known as the input diode static forward current), we could assure that the phototransistor will be in the saturate state (ON), because the minimum current to make the phototransitor on is about 10 mA. The following circuit is use optocoupler to interfacing the relay:

By using 5 Volt power supply and relay with 5 Volt and 60mA operating current:

RC = 0 Ohm (not use, connect relay directly to 5 Volt)

Idiode = 15 mA (0.015 A), VLED = 2 Volt

RB = (VPORT – VLED) / IB = (4.2 – 2) / 0.015 = 146.66 Ohm, use 150 Ohm resistor

P = (VPORT – VLED) x IB = (4.2 – 2) x 0.015 = 0.033 watt, use 0.25 Watt resistor

Idiode = 15 mA (0.015 A), VLED = 2 Volt

RB = (VPORT – VLED) / IB = (4.2 – 2) / 0.015 = 146.66 Ohm, use 150 Ohm resistor

P = (VPORT – VLED) x IB = (4.2 – 2) x 0.015 = 0.033 watt, use 0.25 Watt resistor

If you need to drive more current you could use the Darlington pair circuit above or you could use the high gain Darlington optocopuler such as 4N45 (CTR minimum about 350 %).

F. Controlling your DC motor direction

Using just one transistor to control the DC motor as the above example; we only can turn the DC motor in one direction if we want to change the direction than we also have to change the DC motor voltage polarity. The other way to work around this condition is to use the relay to switch the DC motor’s voltage polarity, but using this method means the DC motor will always ON and we can not control the DC motor speed using digital signal or known as the PWM (Pulse Width Modulation).

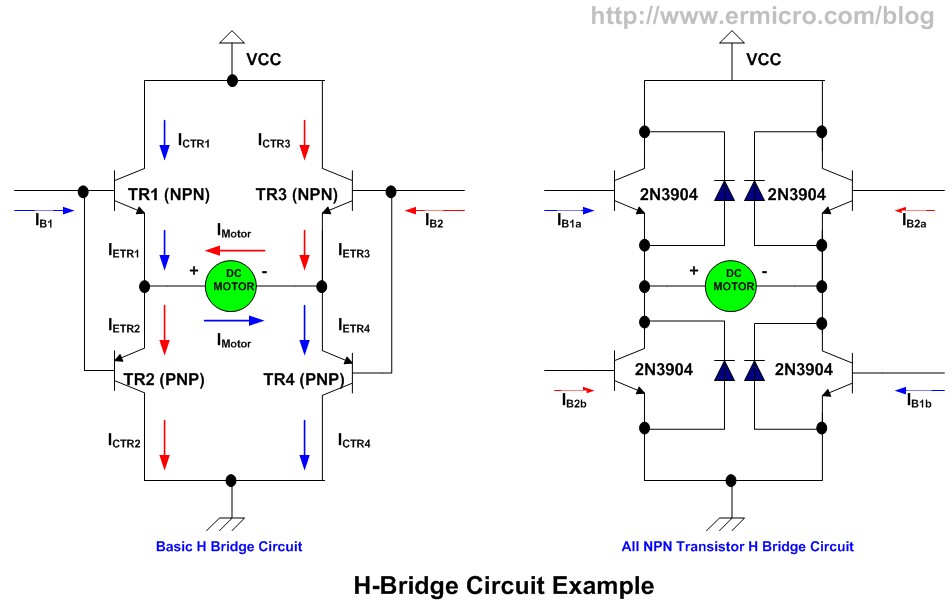

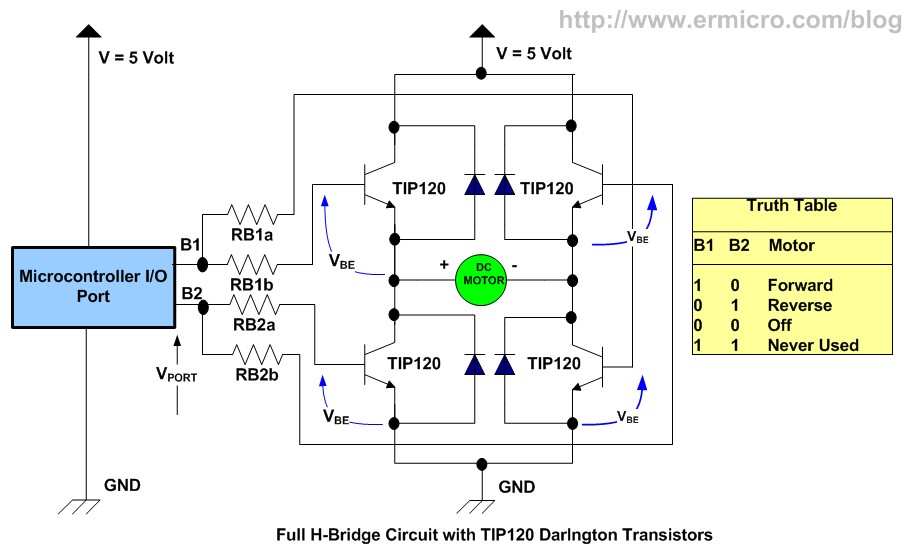

The best and popular way to solve this issue is to use the H-bridge circuit:

When we apply current (IB1) to the TR1 and TR2 transistors, IB2=0 to the TR3 and TR4 transistors, then TR1 and TR4 transistors will be turned ON, TR2 and TR3 will be turned OFF; this will cause the current to start flow through TR1 transistor, passing the DC motor and going into the TR4 transistor (blue color). When we apply current (IB2) to the TR3 and TR4 transistors, IB1=0 to the TR1 and TR2 transistors, then the TR3 and TR2 transistors will be ON while TR1 and TR4 transistors will be turned OFF; this will cause the current to flow through TR3, passing the DC motor in reverse polarity and going into the TR2 transistor (red color). By not applying current to both IB1 and IB2 all the transistors will be turned OFF.

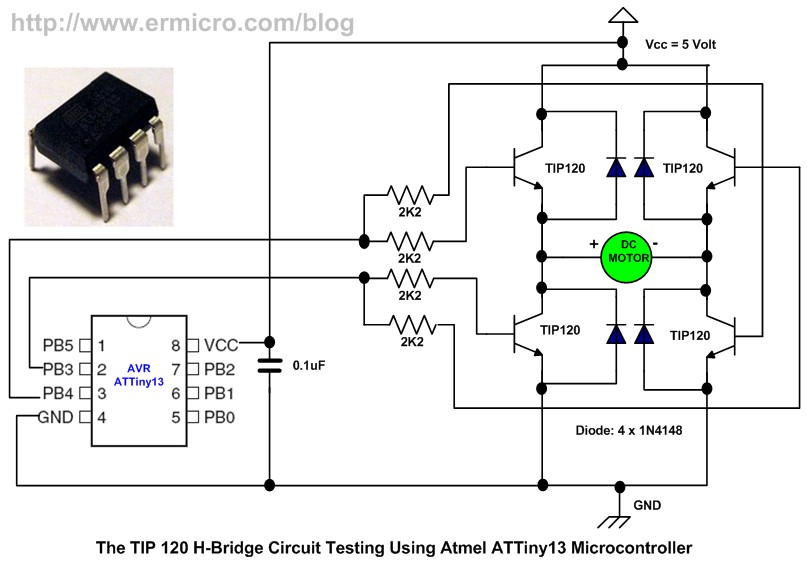

Again by applying the Ohm’s law we could easily calculate the RB1 and RB2 on this following circuit (Updated! Thanks for the nice discussion and correction from the All About Circuits Forum discussionhere, in order for this circuit to work you have to put a resistor on each of the TIP 120 Darlington transistors base terminal):

The above H-Bridge circuit use 5 Volt supply and DC motor with 5 Volt and 1 A maximum operating current rating; assuming the TIP120 Darlington transistor hFE is 1000, the RB1 and RB2 resistors could be calculated as follow:

IB = IC / hFE = 1 A / 1000 = 0.001 A, for each of the transistor base current

RB1a,b = (VPORT – VBE) / IB = (4.2 – 1.4) / 0.001 = 2800 Ohm, use 2K2 Ohm resistor

RB2a,b = (VPORT – VBE) / IB = (4.2 – 1.4) / 0.001 = 2800 Ohm, use 2K2 Ohm resistor

P = (VPORT – VBE) x IB = (4.2 – 1.4) x 0.001 = 0.0028 watt, use 0.25 Watt resistor for RB1 andRB2

RB1a,b = (VPORT – VBE) / IB = (4.2 – 1.4) / 0.001 = 2800 Ohm, use 2K2 Ohm resistor

RB2a,b = (VPORT – VBE) / IB = (4.2 – 1.4) / 0.001 = 2800 Ohm, use 2K2 Ohm resistor

P = (VPORT – VBE) x IB = (4.2 – 1.4) x 0.001 = 0.0028 watt, use 0.25 Watt resistor for RB1 andRB2

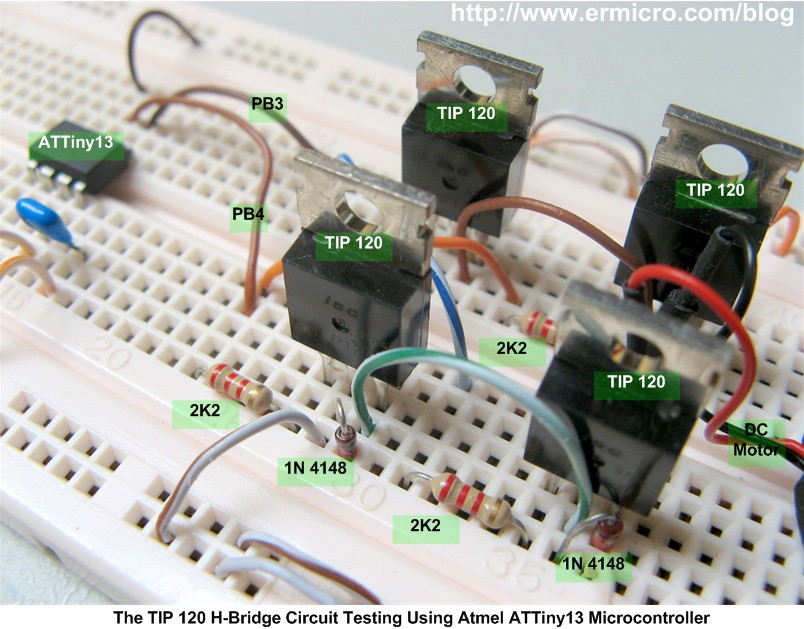

To test the TIP 120 Darlington transistors H-Bridge circuit above I used this following circuit using Atmel AVR ATTiny13 microcontroller as shown on this following picture:

Bellow is the C Program that I used to test this circuit:

//*************************************************************************** // File Name : trhbridge.c // Version : 1.0 // Description. : Transistor as Switch: Simple All TIP120 H-Bridge // Author : RWB // Target : Atmel AVR ATTiny13 Microcontroller // Compiler : AVR-GCC 4.3.2; avr-libc 1.6.2 (WinAVR 20090313) // IDE : Atmel AVR Studio 4.17 // Programmer : Atmel AVRISPmkII // Last Updated : 18 June 2010 //*************************************************************************** #include <avr/io.h> #include <util/delay.h>

int main(void)

{

// Initial I/O

DDRB |= (1<<PB3)|(1<<PB4); // Set PB3,PB4 as Output, Others as Input

PORTB &= ~(1<<PB3); // Reset PB3 (OFF)

PORTB &= ~(1<<PB3); // Reset PB4 (OFF)

for(;;) { // Loop Forever

PORTB |= (1<<PB3); // Turn ON PB3

_delay_ms(3000); // Delay 3 Second

PORTB &= ~(1<<PB3); // Turn OFF PB3

_delay_ms(2000); // Delay 2 Second

PORTB |= (1<<PB4); // Turn ON PB4

_delay_ms(3000); // Delay 3 Second

PORTB &= ~(1<<PB4); // Turn OFF PB4

_delay_ms(2000); // Delay 2 Second

}

return 0; // Standard Return Code

}

/* EOF: trhbridge.c */

One of the advantage using all NPN transistors in the H bridge circuit is the NPN transistor tends to have faster turn on time comparing to the PNP transistor, beside by using the same transistor type we could have similar transistor characteristic in the circuit. You could read more example of using all NPN transistor H-Bridge in “H-Bridge Microchip PIC Microcontroller PWM Motor Controller” on this blog.

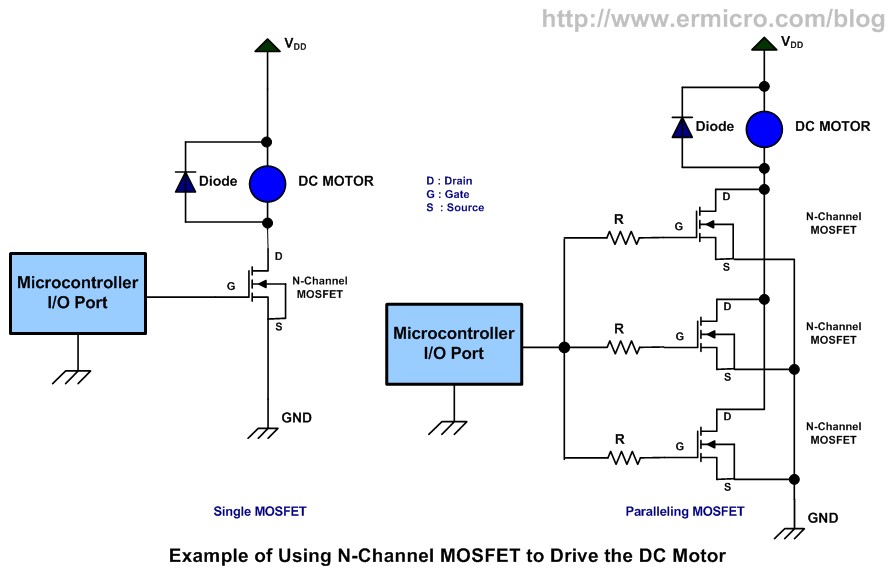

Actually most of the modern H-Bridge circuit design for higher voltage (e.g. more than 9 volt) is rarely use the BJT anymore; instead we use the MOSFET because MOSFET is more efficient on higher voltage (i.e. less power dissipation) compare to the ordinary BJT. The other advantage of using MOSFET is that it has very high input impedance, therefore we could easily connect parallel a couple of the same MOSFET to achieve the higher current output and at the same time we could decrease the output resistance of the MOSFET (Rds), which mean we could get more lower power dissipation as shown on this following picture:

The “The Line Follower Robot with Texas Instruments 16-Bit MSP430G2231 Microcontroller” article is a good example of how we use the N-Channel MOSFET to control the DC motor.

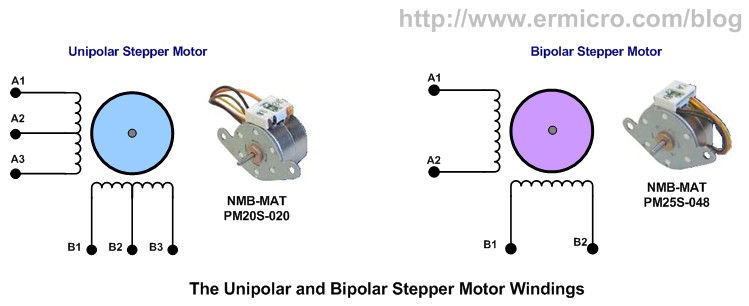

Driving the Stepper Motor

One type of the brushless electric motor that is designed specifically for digital signal input is called the stepper motor. The stepper motor usually is used when we need to control the precise rotation movement and speed with the open loop control. These advantages make the stepper motor is widely found in many applications such as printers, scanners, disk drives, automotives, CNC machines, toys, and many more.

Today the most common used stepper motor types are Unipolar Stepper Motor and Bipolar Stepper Motor. The unipolar stepper motor usually has two windings with a center tap on each of windings, therefore the current could move from the center tap either to the left winding or to the right winding. Usually the unipolar stepper motor comes with 5 or 6 terminal leads. On the other hands the bipolar stepper motor actually is similar to the unipolar type but without the center tap.

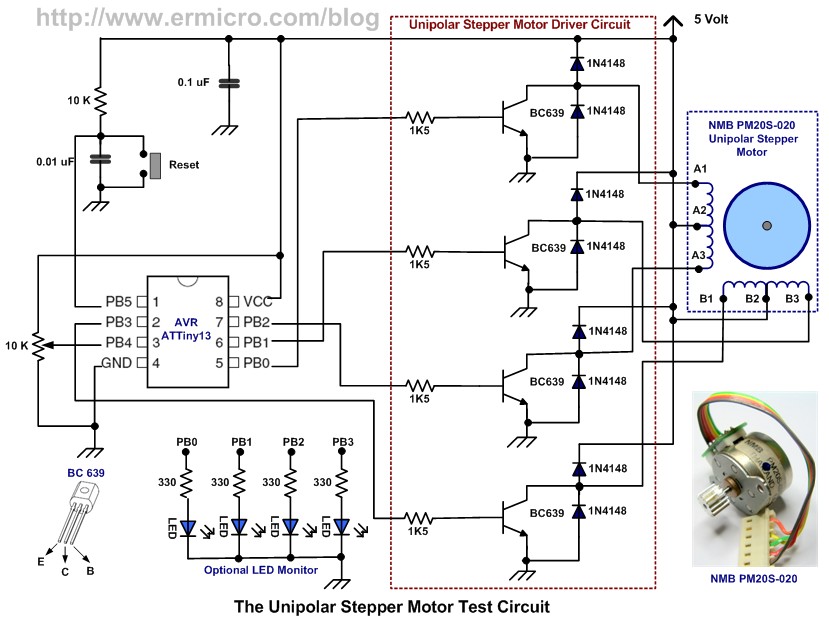

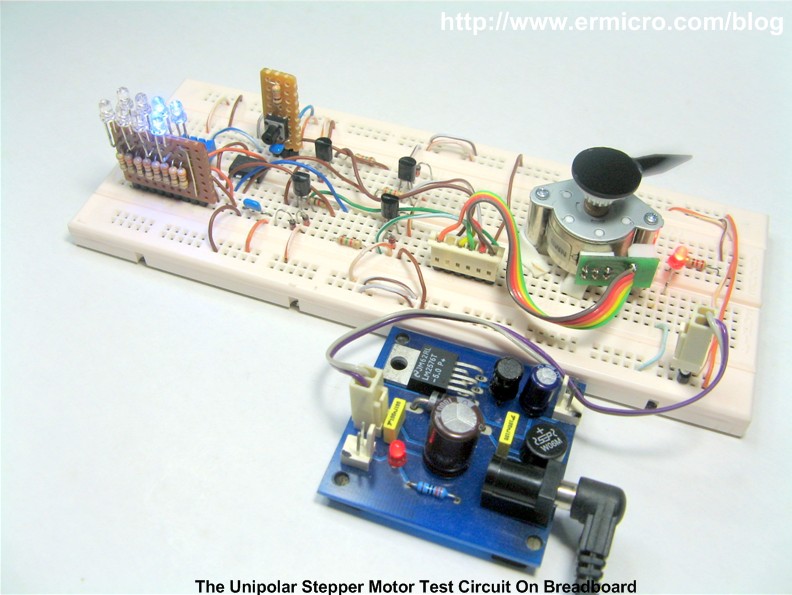

Therefore the unipolar stepper motor has advantage of more simple driving circuit over the bipolar stepper motor but has a torque less than the bipolar motor for the same size. The following circuit uses four BC639 transistors to drive the unipollar stepper using the Atmel AVR ATTiny13 microcontroller to provide the required stepping signal to the unipolar stepper motor:

From the schematic above you could see that each transistor is connected to half windings of the unipolar stepper motor phase. You need to experiment with your own stepper motor to get the right windings connection. Assuming maximum 100 mA unipolar stepper motor current on 5 volt supply, and using minimum BC 639 transistor hFE of 40, we could calculate the RB (the base resistors) as follow:

IB = IC / hFE = 100 mA / 40 = 0.0025 A

RB = (VPORT – VBE) / IB = (4.2 – 0.7) / 0.0025 = 1400 Ohm, use 1K5 Ohm resistor

P = (VPORT – VBE) x IB = (4.2 – 0.7) x 0.0025 = 0.0086 watt, use 0.25 watt resistor

RB = (VPORT – VBE) / IB = (4.2 – 0.7) / 0.0025 = 1400 Ohm, use 1K5 Ohm resistor

P = (VPORT – VBE) x IB = (4.2 – 0.7) x 0.0025 = 0.0086 watt, use 0.25 watt resistor

Two clamp diodes on each transistor are required because the winding has a center tap. Therefore when one end of winding is high (Vcc) the other end is low (GND) the lower diode will bypass the back EMF (Electromotive Force) voltage that appear on BC 639 transistor collector and emitter terminals.

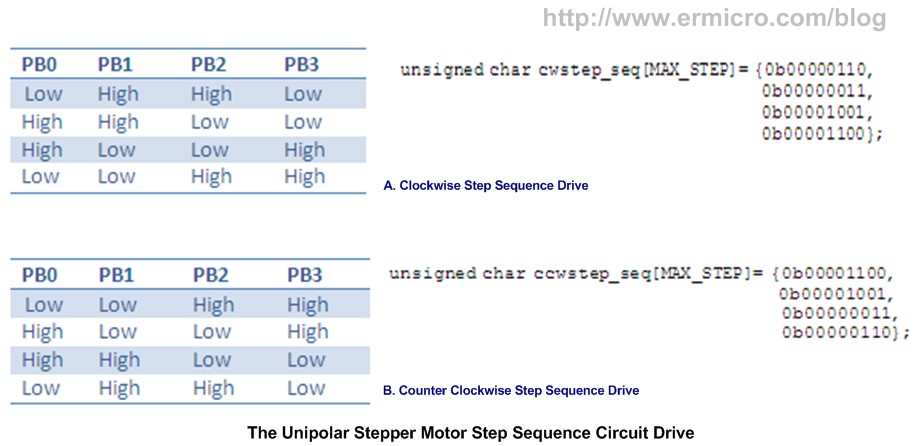

This following is the C code is used for testing the circuit above:

//*************************************************************************** // File Name : upstepper.c // Version : 1.0 // Description. : Transistor as Switch: Simple Unipolar Stepper // Motor Driver - Full Step Method // Author : RWB // Target : ATTiny13 // Compiler : AVR-GCC 4.3.2; avr-libc 1.6.2 (WinAVR 20090313) // IDE : Atmel AVR Studio 4.17 // Programmer : Atmel AVRISPmkII // Last Updated : 03 Nov 2010 //***************************************************************************

#include <avr/io.h> #include <util/delay.h> #include <avr/interrupt.h>

// Unipolar Stepper Motor CW/CCW Stepping Sequence #define MAX_STEP 4

unsigned char cwstep_seq[MAX_STEP]= {0b00000110,

0b00000011,

0b00001001,

0b00001100};

unsigned char ccwstep_seq[MAX_STEP]= {0b00001100,

0b00001001,

0b00000011,

0b00000110};

volatile unsigned char step_index;

volatile unsigned int ovftimes;

volatile unsigned char status;

ISR(TIM0_OVF_vect)

{

static unsigned int count=1;

count++;

if (count >= ovftimes) {

cli(); // Disable Interrupt

// Stepping Output

if (status)

PORTB = ccwstep_seq[step_index++];

else

PORTB = cwstep_seq[step_index++];

if (step_index >= MAX_STEP)

step_index=0;

count=0; // Reset Count

TCNT0=0; // Start counter from 0

sei(); // Enable Interrupt

}

}

int main(void)

{

// Initial I/O

DDRB = 0b00001111; // Set PB0, PB1, PB2, and PB3 as Output, Others as Input

PORTB = 0b00000000; // Reset PORTB Output

// Set ADCSRA Register on ATTiny13 ADCSRA = (1<<ADEN) | (1<<ADPS2) | (1<<ADPS1); ADCSRB = 0b00000000;

// Set ADMUX to PB4 (ADC2) ADMUX=0b00000010;

// Disable Digital Input on PB4 (ADC2) DIDR0=0b00001000;

// Initial TIMER0 TCCR0A=0b00000000; // Timer/Counter 0 Normal Operation TCCR0B=(1<<CS01); // Use prescaller: Clk/8 with 9.6 MHz Internal Clock TCNT0=0; // Start counter from 0 TIMSK0=(1<<TOIE0); // Enable Counter Overflow Interrupt

step_index=0; ovftimes=10; status=0; // 0 - CW, 1 - CCW

sei(); // Enable Interrupt

for(;;) { // Loop Forever

// Start conversion by setting ADSC on ADCSRA Register

ADCSRA |= (1<<ADSC);

// wait until convertion complete ADSC=0 -> Complete

while (ADCSRA & (1<<ADSC));

// Get the ADC Result

ovftimes = ADCW;

if (ovftimes > 800)

status^=0x01; // Toggle the Direction

_delay_ms(50);

}

return 0; // Standard Return Code

}

/* EOF: upstepper.c */

The method to rotate this unipolar stepper motor rotor is known as the full step mode method; in full step mode we always excite two windings at the same time, with the right current sequence we could rotate the stepper motor in 4 repeatable steps. Reversing the step sequences will make the stepper motor to turn into opposite direction. In this tutorial I used NMB-PM20S-020 permanent magnet motor where the step required is shown on this following diagram:

You could easily adapt the step sequence to your own unipolar stepper motor by changing both thecwstep_seq (clockwise rotation) and ccwstep_seq (counter clockwise rotation) array variables data in the program.

Using the AVR ATTiny13 microcontroller TIMER0 interrupt we could easily supply the required output steps to the stepper motor. I used the ADC (Analog to Digital Conversion) to control the stepper motor step sequence delay as well as to change the rotation direction by adjusting the 10K trimport. For more information about AVR ADC and TIMER0 you could read these blog’s articles “Analog to Digital Converter AVR C Programming” and “Working with AVR microcontroller Communication Port Project“.

You could also replace the BC639 transistor with the Darlington pair transistor array such as ULN2803A from Texas Instrument mention above. Using this Darlington pair transistor array make the unipolar stepper circuit become simpler (less components) because it has the required clamp diode on each Darlington transistor pair and you could take advantage of higher current gainer provided by the Darlington pair transistors.

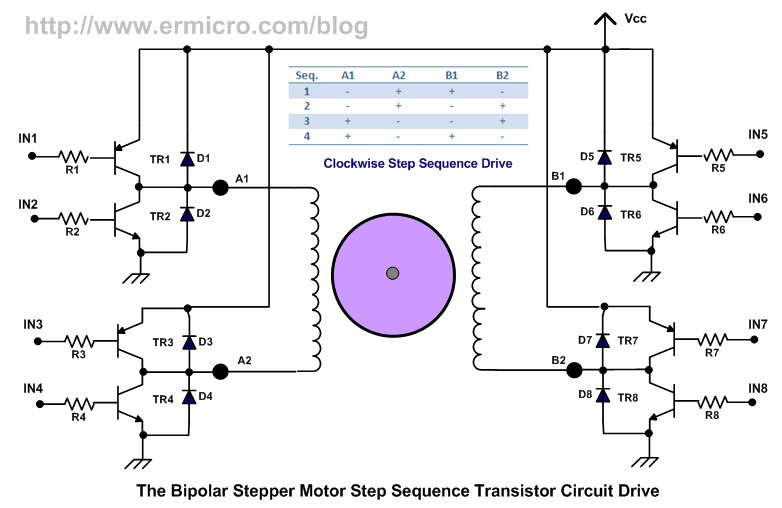

To drive the bipolar stepper motor; each of the two windings will require the H-Bridge circuit similar to the H-Bridge circuit for driving the DC motor mention above. Therefore we need at least 8 transistors to drive the bipolar stepper motor (4 transistors on each windings). By forwarding and reversing the current flow on each winding we could achieve the required steps sequence to drive the bipolar motor.

And by supplying the correct steps sequence logic to IN1, IN2, IN3, IN4, IN5, IN6, IN7, and IN8input from the microcontroller output port we could make this bipolar stepper motor to rotate. The opposite direction (counter clockwise) rotation could be achieved by reversing the steps sequence (i.e. 4, 3, 2, and 1).

Using Transistor as switch Testing Circuit Video

1. This following video show you of how to drive a transistor which connected with 5 red LED using the Atmel AVR ATTiny25 microcontroller.

2. The TIP120 H-Bridge Testing Circuit video using Atmel ATTiny13 Microcontroller:

3. The Unipolar Stepper Motor Testing Circuit video using Atmel ATTiny13 Microcontroller:

沒有留言:

張貼留言