源自於 http://www.ermicro.com/blog/?p=1908

Designing a simple and yet functional Line Follower Robot (LFR) is always a fascinating and challenging subject to be learned, the LFR actually could be implemented in many ways start from a simple two transistors to a sophisticated PID (Proportional, Integrate and Differential) which take advantage of the programmable feature of microcontroller to calculate the PID equation to successfully navigate the black track line on a white background surface.

Designing a non microcontroller based LFR is quite challenging tasks as we need to limit the electronic components numbers so the LFR will not too complicated to be built by most average robotics beginners or electronic hobbyists, but at the same time we need to have a good speed control mechanism in order for the LFR to navigate the black track line successfully. The microcontroller based design LFR in the other hand is a popular choice because it reduces a number of electronic components significantly while still providing a flexible programmable control to the LFR.

On this tutorial we are going to build yet another LFR using just the standard analog components easily found on the market but use the same speed control method technique found in many good microcontroller based Line Follower Robot design. As the result we could get a good precision analog line follower robot that comparable to the microcontroller based Line Follower Robot design. On this tutorial you will also learn many useful information of how to use the operational amplifier.

The Line Follower Robot

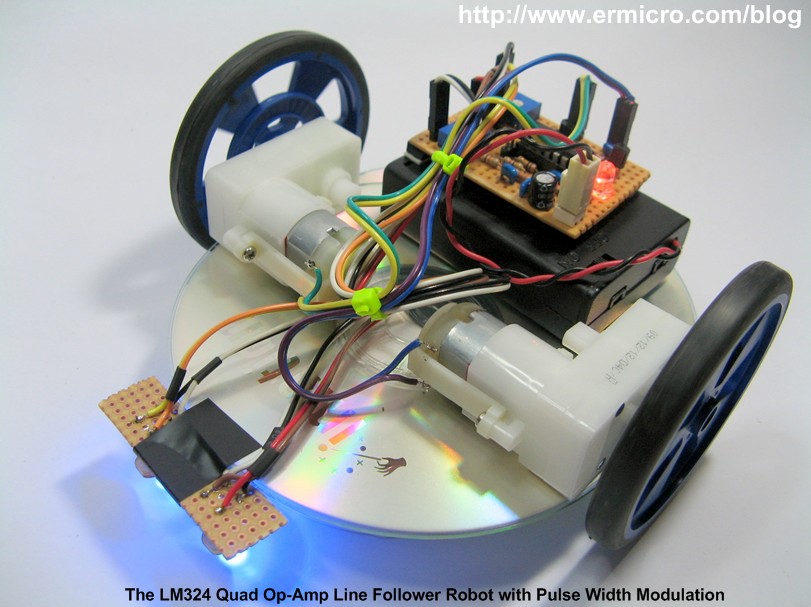

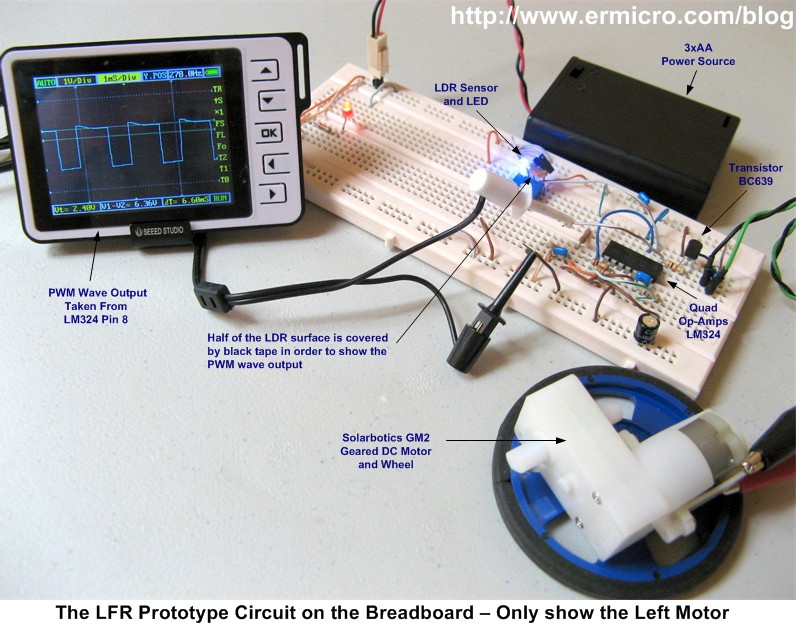

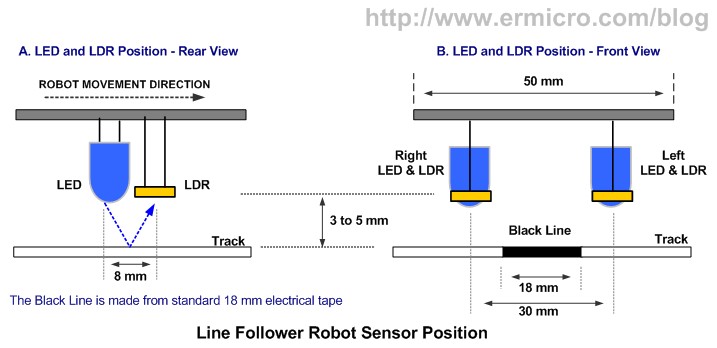

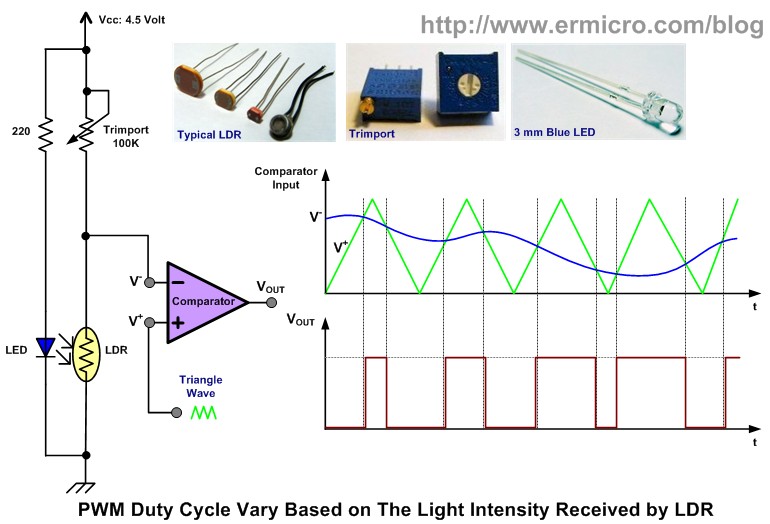

This Line Follower Robot basically use a Cadmium Sulphide (CdS) photocell sensor or known as Light Dependent Resistor (LDR) and the high intensity blue Light Emitting Diode (LED) to illuminate the area under the photocell sensor to sense the black track line and the DC motor speed control technique to navigate the black line track as shown on this following picture:

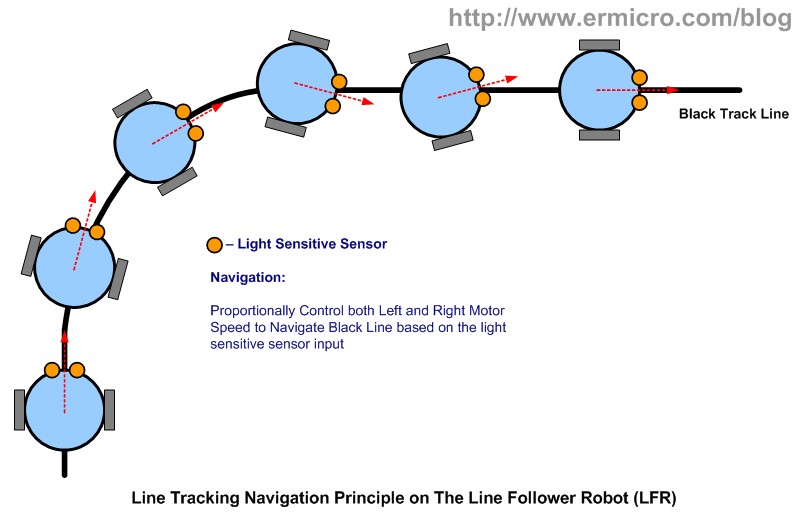

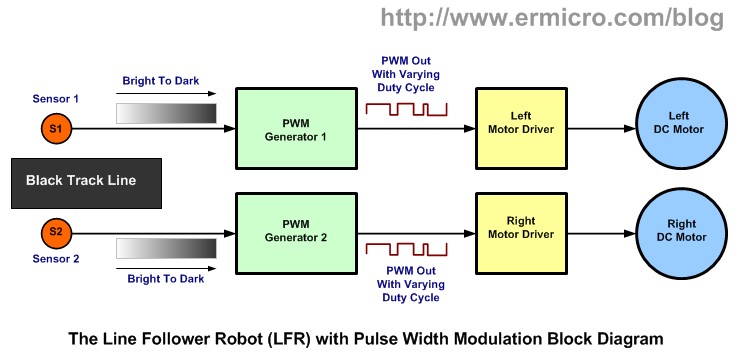

The easy method to navigate the black track line is to turn ON and OFF the left or the right DC motor according to the sensor reading (black turn OFF and white turn ON), but using this method will make the LFR to move in zigzag way. By proportionally control both left and right DC motor speed according to the light intensity level received by the photocell sensor (reflected back by the black track line) we could make the LFR easily navigate this track. The common technique to control the motor speed efficiently is to use a pulse signal known as the pulse width modulation or PWM for short.

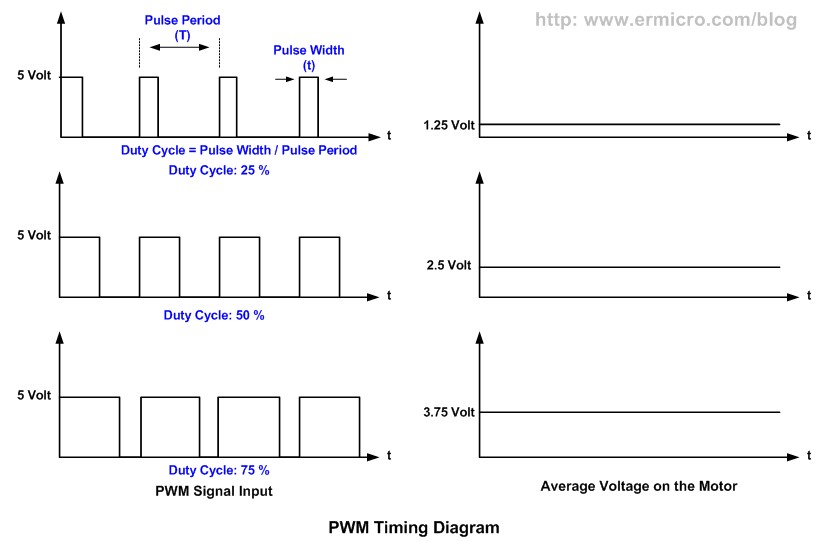

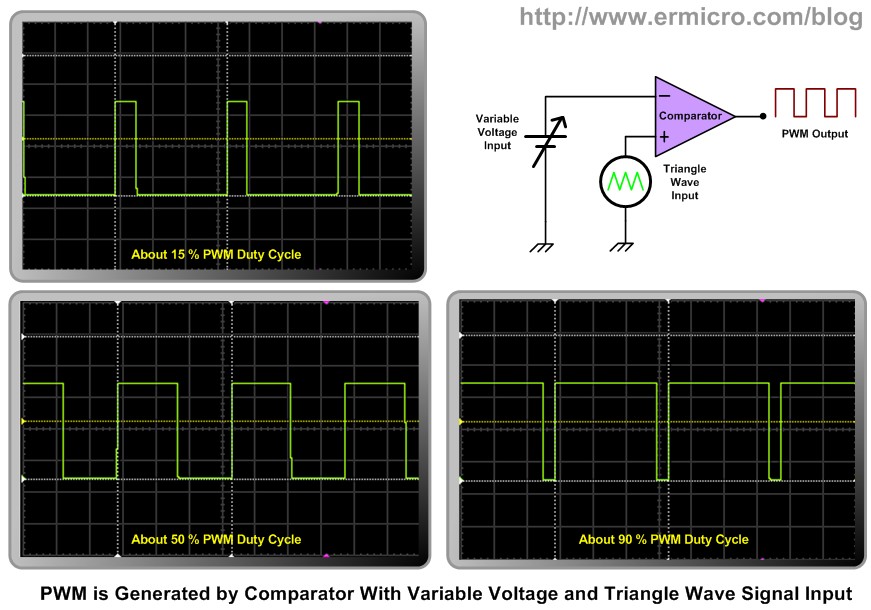

PWM basically is an ON and OFF pulse signal with a constant period or frequency. The proportion of pulse ON time to the pulse period is called a “duty cycle” and it expressed in percentage. For example if the proportion of pulse ON time is 50% to the total pulse period than we say that the PWM duty cycle is 50%. The PWM duty cycle percentage is corresponding to the average power produced by the pulse signal; the lower percentage produces less power than the higher percentage.

Therefore by changing the PWM duty cycles we could change the average voltage across the DC motor terminals, this mean we could vary the DC motor speed just by changing the PWM duty cycle. Therefore to make the LFR smoothly navigate the black track line, we have to adjust the PWM duty cycle according to the photocell sensor reading. The brighter light intensity level received by sensor (sensor is on the white surface) will result in higher PWM duty cycle percentage and the darker light intensity level (sensor is on the black line) received by photocell sensor will result in lower PWM duty cycle percentage.

By converting each of the photocell sensor light intensity level reading to the corresponding voltage level we could achieve this objective by using what is known as the Voltage Control Pulse Width Modulation principal.

Actually generating the PWM signal is easier with microcontroller instead of discrete components because all you have to do is to program the microcontroller PWM peripheral to do the task. On this tutorial we will learn of how to build this LFR with Voltage Control PWM using the same working principal found in many today’s modern microcontroller but using just the analog electronic components.

Now let list down the necessary electronic and other supported components to build this awesome LFR:

1. Resistors: 220 (2), 1K (2), 15K (1), 33K (1), 47K (2), and 100K (1)

2. Trimpots: 100K (2)

3. Two Light Dependent Resistor (dark above 100KOhm and below 5KOhm on bright light intensity)

4. Capacitors: 47uF/16v (1) and 0.1uF (5)

5. Diodes: 1N4148 (2)

6. High Intensity 3 mm blue Light Emitting Diode (2)

7. Optional 5 mm auto flash RGB LED with 330 Ohm resistor for the power indicator

8. Transistors: BC639 (2)

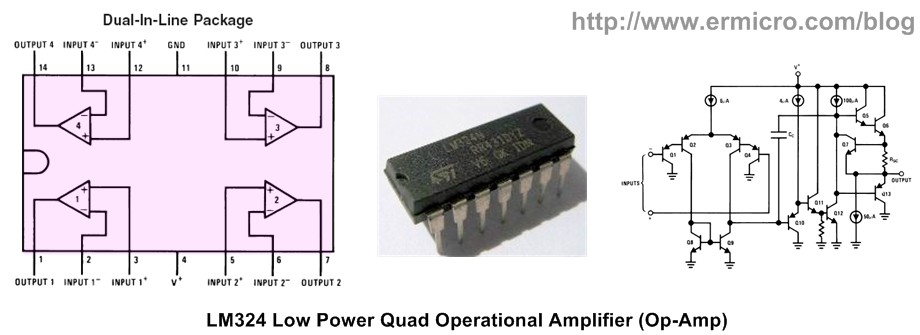

9. IC: National Semiconductor LM324 Quad Operational Amplifier (1)

10. DC Motor: Solarbotics GM2 Geared DC motor with Wheel (2)

11. Prototype Board: 52 x 38 mm for main board and 50 x 15 mm for sensors

12. 3xAA Battery holder

13. CD/DVD ROM (2)

14. Plastic Beads and Paper Clip for the castor (the third wheel)

15. Bolt, Nuts, Double Tape and Standard Electrical Tape for the black line

2. Trimpots: 100K (2)

3. Two Light Dependent Resistor (dark above 100KOhm and below 5KOhm on bright light intensity)

4. Capacitors: 47uF/16v (1) and 0.1uF (5)

5. Diodes: 1N4148 (2)

6. High Intensity 3 mm blue Light Emitting Diode (2)

7. Optional 5 mm auto flash RGB LED with 330 Ohm resistor for the power indicator

8. Transistors: BC639 (2)

9. IC: National Semiconductor LM324 Quad Operational Amplifier (1)

10. DC Motor: Solarbotics GM2 Geared DC motor with Wheel (2)

11. Prototype Board: 52 x 38 mm for main board and 50 x 15 mm for sensors

12. 3xAA Battery holder

13. CD/DVD ROM (2)

14. Plastic Beads and Paper Clip for the castor (the third wheel)

15. Bolt, Nuts, Double Tape and Standard Electrical Tape for the black line

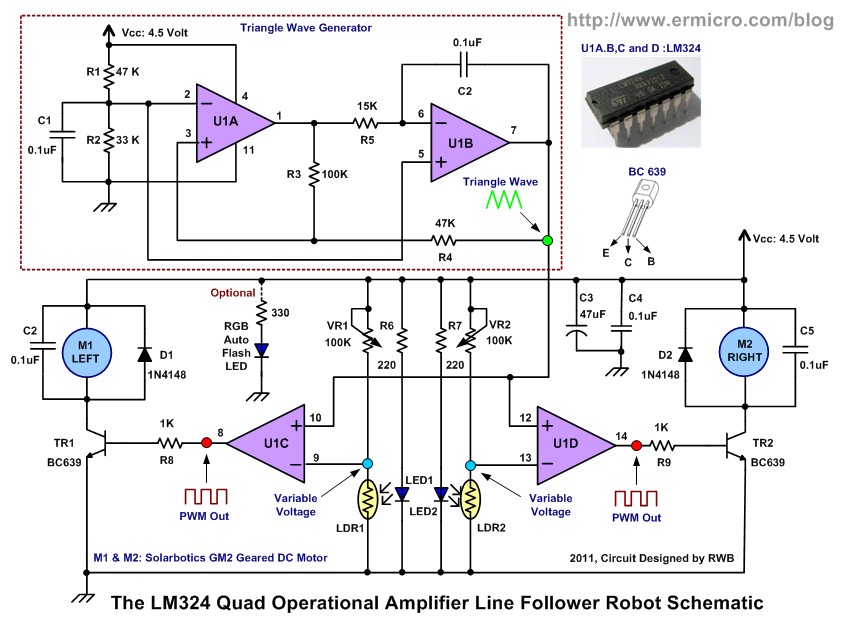

The complete Line Follower Robot electronics schematic is shown on this following picture:

The Voltage Control PWM

The main brain of this Line Follower Robot is lay behind the LM324 quad operational amplifier from National Semiconductor. The dual in line LM324 packages contains four identical op-amps and is specially designed to operate as an analog device.

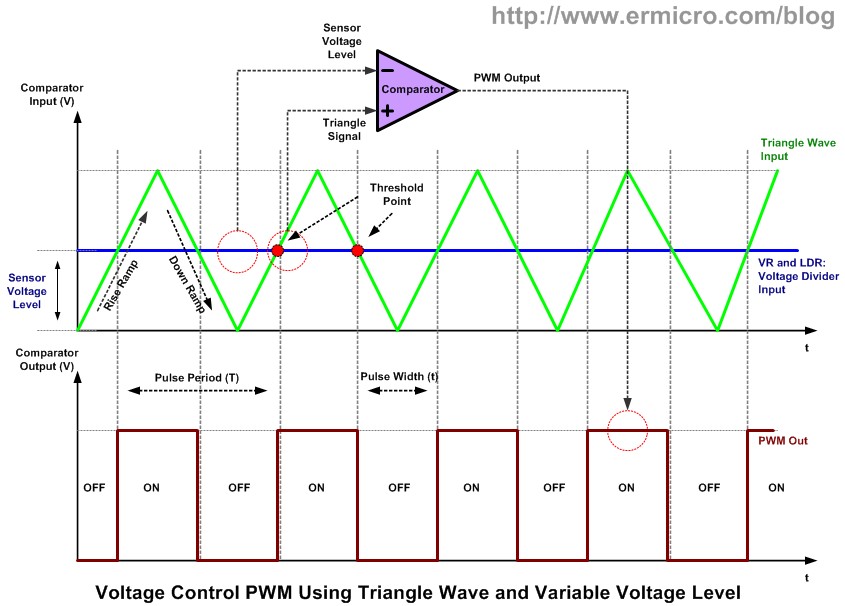

The voltage control PWM could be generated by first using the triangle signal generator which provide the basic PWM pulse frequency and the necessary ramp voltage (rise and down) to produce the PWM signal. Next by continuously comparing this ramp voltage according to the voltage level produced by the photocell sensor using the comparator circuit we could produced the exact voltage control PWM as shown on this following picture.

When the triangle rise ramp signal reaches the voltage threshold point it will turn ON the comparator because the comparator non inverting input (V+) voltage is greater than the comparator inverting input (V-) voltage and when the down ramp signal reaches the voltage threshold point it will turn OFF the comparator because now the comparator inverting input (V-) voltage is greater than the comparator non inverting input (V+) voltage. You could read more about how the comparator works on Working with the Comparator Circuit in this blog.

If we set the threshold point voltage higher, then the ON period will be shorten; and if we set the threshold point voltage lower, then the ON period will be longer. Therefore by varying the threshold point voltage we could also vary the ON and OFF period of the comparator which is the exact behavior that we are looking for to produce the required PWM signal to drive the Line Follower Robot geared DC motor.

The ramp signal is provided by the two op-amps (U1A and U1B) that generate the triangle wave signal while the comparator for producing the PWM to each DC motor is provided by the other two op-amps (U1C and U1D) that receipt its input from the voltage divider circuit (VR and LDR) which provide the voltage threshold point and together with the triangle wave to produce the required PWM pulse

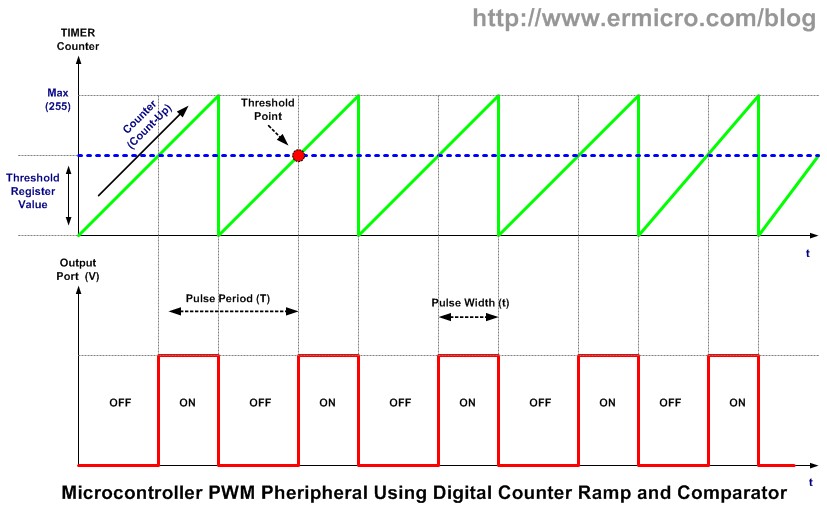

The PWM principal explained above is also used in many today’s modern microcontrollers PWM peripheral; but instead of processing the analog signal it process the digital signal. The ramp signal is replaced by the digital counter (TIMER peripheral) that will count up from 0 to 255 and start from 0 again, while the threshold point voltage is provided by threshold point register that hold the digital value (e.g. 100).

Microcontroller uses the digital comparator to compare these two digital values, when the digital counter counting up and reach the threshold point (i.e. 100) then the PWM peripheral will turn on to the output port and when it reach the maximum value (i.e. 255) it will turn off to the output port. Therefore by changing the threshold point register value we could change the PWM duty cycle output. You could read more about microcontroller based PWM on H-Bridge Microchip PIC Microcontroller PWM Motor Controller and Introduction to AVR Microcontroller Pulse Width Modulation (PWM) articles on this blog.

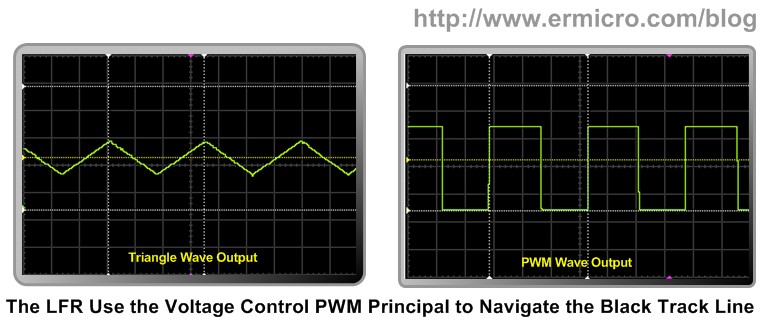

When designing the electronic circuit is a good habit to prototype it first, the prototype circuit enables us to fine tune the electronics design and give us the picture (signal wave) of how the circuit really works. The following picture is the Line Follower Robot circuit prototype on a breadboard complete with sensor (LED and LDR pairs) and the GM2 geared DC motor from Solarbotics.

The Triangle Wave Generator Circuit

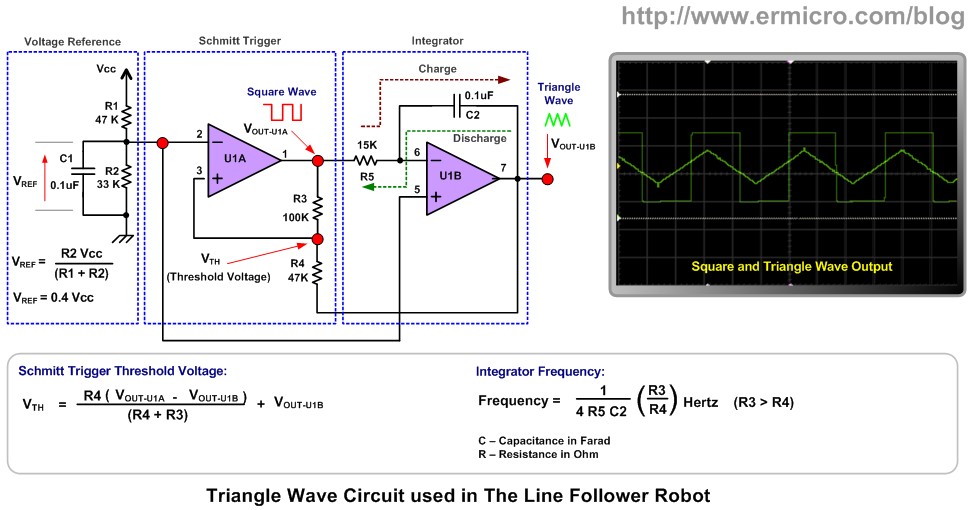

Now as you understand the principal of how the Line Follower Circuit works than let’s take a look at the triangle wave generator circuit. In order to make it easy to understand I redraw the electronic schematic circuit separately as shown on this following picture:

To generate the triangle wave we need to use the Schmitt Trigger circuit (also called a comparator with hysteresis) that act as ON and OFF switch to the Integrator circuit input. The integrator uses the R5 and C2 to produce the necessary triangle linear ramp (up and down) on its output.

When the power up we assume the U1A output is HIGH (Vcc); the C2 capacitor will start to charge through the R5 resistor. Because the R5 and C2 is connected to the U1B inverting input (V-), therefore the U1B output will start to ramp down. The U1A non inverting input (V+) get the positive feedback from R3 and R4, when the U1B output voltage reach the threshold voltage below Vref than it will turn the U1A output to LOW (0). This bottom threshold voltage could be calculated as follow:

Vth = (R4 (Vout-u1a – Vout-u1b) / (R4 + R3)) + Vou-u1b; Vout-u1a = Vcc; Vcc = 4.5 Volt

Vth <= Vref, Vref = 0.4 Vcc

(R4 (Vcc – Vout-u1b) / (R4 + R3)) + Vout-u1b <= 0.4 Vcc

Now putting all the resistors value then we will get this following result:

(47 (Vcc – Vout-u1b)/ 147) + Vout-u1b <= 0.4 Vcc

1.4 – 0.3 Vout-u1b + Vout-u1b <= 1.8

Vout-u1b <= 0.6 Volt

Therefore the U1B output will ramp down to about 0.6 volt than the U1A output will turn OFF. Next the C2 capacitor will discharge through R5 and the UA1B output will start to ramp up and it start to increase the voltage across the R4 (Vth – threshold voltage) until the Vth voltage above the Vref voltage then the U1A output will turn to HIGH and the whole cycle will repeat again. This upper threshold voltage could be calculated as follow:

Vth = (R4 (Vout-u1a – Vout-u1b) / (R4 + R3)) + Vou-u1b; Vout-u1a = 0; Vcc = 4.5 Volt

Vth >= Vref; Vref = 0.4 Vcc

(R4 (- Vout-u1b) / (R4 + R3)) + Vout-u1b >= 0.4 Vcc

Now putting all the resistors value then we will get this following result:

(47 (- Vout-u1b)/ 147) + Vout-u1b >= 0.4 Vcc

- 0.3 Vout-u1b + Vout-u1b >= 1.8

Vout-u1b >= 2.6 Volt

Therefore the triangle voltage will ramp up from 0.6 volt to 2.6 volt then ramp down to 0.6 volt repeatedly. The frequency of the triangle wave could be calculated as follow:

Frequency = (1 / (4 x R5 x C2)) x (R3/R4) Hertz

Now putting all the resistors and capacitor value then we will get this following result:

Frequency = (1 / (4 x 15,000 x 0.0000001)) x (100,000/47,000) = 354.61 Hz

As you might guess the actual frequency measured on this Line Follower Robot prototype circuit above is about 292 Hz, this is due to the electronic components tolerance value (resistors and capacitors). Therefore if you want to have the exact frequency you could put a 100K trimport in series with R5 resistors. The voltage divider R1 and R2 provide the voltage reference (DC bias voltage) to both U1A and U1B op-amps.

The Sensor Circuit

As mention above this Line Follower Robot take advantage of the photo-resistor (CdS) known as Light Dependent Resistor (LDR). The LDR will decreases its resistance in the presence of light and increase its resistance in the dark. The region under the LDR is illuminate with a high intensity blue LED, the white surface will reflect most of the light to the LDR surface while the black track line will absorb most of the light, therefore less light will reflect to the LDR surface.

As the robot move on the black track line the LDR will continuously capture the reflected light and convert this light intensity into the corresponding voltage and feeding it to the inverting input (V-) of U1C (left sensor) and U1D (right sensor).

The 100K trimpot and LDR basically is the voltage divider circuit when the LDR detect the black track line it will receive less light intensity (LDR resistance increase) and the voltage (V-) will increase; this will decrease the PWM duty cycle output and as the result the geared DC motor will turn slowly or stop. When the LDR on the white surface it will receive maximum light intensity (LDR resistance decrease) and the voltage (V-) will decrease; this will increase the PWM duty cycle output and as the result the geared DC motor will turn fast.

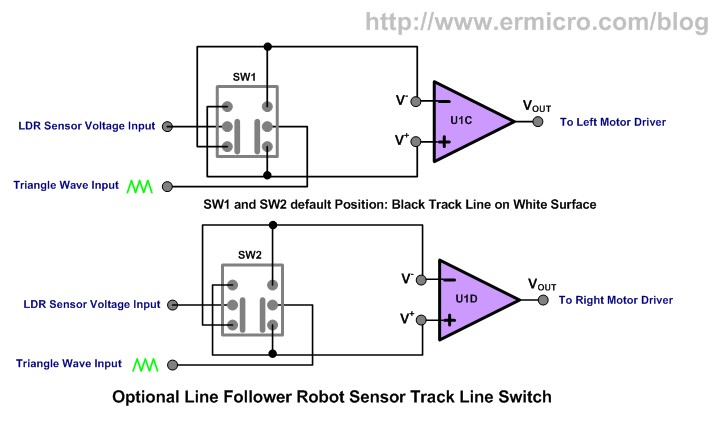

You could simply exchange the comparator V+ and V- input source to make the Line Follower Robot detect the white line on the black surface instead of normal black line on the white surface. By using two DPDT (Double Pole Double Throw) switches you could achieve this behavior as shown on this following picture:

The geared DC motor driver uses the BC639 transistor and the base terminal is connected to the comparator output through the 1K resistor. The transistor is operated as a switch which turns ON and OFF the geared DC motor according to the PWM pulse current it received from the comparator. The 0.1uF capacitor across the geared DC motor’s terminal is used to reduce noise generated by the DC motor. For more information about using transistor as switch you could read Using Transistor as Switch article on this blog.

The Line Follower Robot Construction

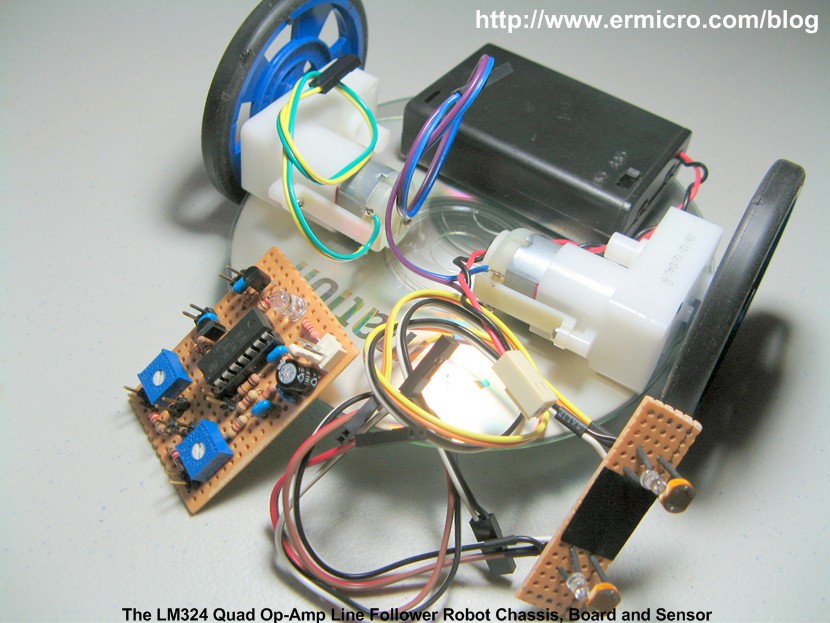

The Line Follower Robot construction could be constructed freely but the easiest one is to use the discarded CD/DVD ROM as shown on this following pictures:

I glue the two CDROM together in order to make more room and attached the two DC motors, 3xAA battery holder, main board and sensor board using the double tape. The sensor sensitivities and the Line Follower Robot speed could be controlled by adjusting the 100K trimport. After putting all the parts together now is time to watch how this nice Line Follower Robot in action:

The Final Thought

As you’ve seen from the demo video above this Line Follower Robot design is capable to handle and smoothly navigate a quite complex black track line. This prove that a good analog Line Follower Robot design sometimes could outperform many microcontrollers based Line Follower Robot.

Building the Line Follower Robot (LFR) is one of my favorite projects as I enjoy designing and making this kind of robot, it also gives much joy and fun to my kids as well. I hope this project will give you as much joy as I did; building, watching, and playing with this analog Line Follower Robot.

Hii Iam using LM324 IC comparator for solar tracking system for detecting high light intensity and I used node mcu to route the pannel direction using servo motor but how to take values in node mcu with single analog pin

回覆刪除i refered the below link while purchasing it

http://bigbelectronics.in/product.php?product=lm324n-operational-amplifier-quad-4-amplifier-1-2-mhz-0-5-v-us-3v-32v-1-5v-16v-dip

please provide with some suggestions thank you